Thermal imaging camera is the ideal tool for oil leak detection

On April 6, 2015, a PX project factory in Gulei Port Economic Development Zone, Zhangzhou City, Fujian Province exploded. Witnesses at the scene said that the fire caused by the explosion brightened the night sky, the smoke was rolling, and the accident caused huge property losses. At the same time, the safety problems of the PX project and the petrochemical industry were once again pushed to the public's vision.

How does the US PX factory prevent leaks?

Any accident can be avoided, and it is more important to prevent accidents than to remedy afterwards. In the guidebook of Chevron Phillips in the United States, the precautions for PX storage are listed separately. In the storage and transportation equipment involved, parts such as "storage tank", "filter", "conveying pipeline", "smoke control system" are explained one by one. The “storage tank” section says that the PX must be stored in a welded steel structure container. It is not recommended to use an underground warehouse to avoid easy cleaning after a leak. If you have to use an underground warehouse to store the PX, you should have a keen leak warning system.

The embankment, drainage system and storage tank support shall be constructed in strict accordance with local regulations. The storage tank containment for secondary containment shall be constructed in accordance with the standards of the American Fire Protection Association. Ventilation equipment should be based on the protection of the surrounding environment as much as possible. Considering that the PX freezing point is only 13.3 degrees Celsius, the tank should be equipped with external heating pads and insulation. According to the American Petroleum Institute, the tank must be regularly tested for leak prevention.

How to prevent the petrochemical industry?

Petrochemical production has different characteristics from other industries. Many important equipments work under high temperature and high pressure conditions, and most of them are process operations, long cycle operations, and inherent risks in petrochemical production (flammable, easy Explosion), the industrial production department has always attached great importance to the strict online monitoring of the production process, the reliability and safety of the equipment itself and regular shutdown maintenance. The measurement of surface temperature has important significance for petrochemical equipment. The heating equipment and heat pipes in the petrochemical industry are very numerous. The surface temperature indicates the amount of heat dissipated, which is closely related to energy saving. The temperature distribution on the outer wall surface of the equipment, Mainly determined by the internal working temperature, equipment structure, material thermal resistance and ambient temperature. When the equipment works and the environmental impact is certain, the change of the surface temperature distribution of the equipment directly reflects the change of the equipment condition.

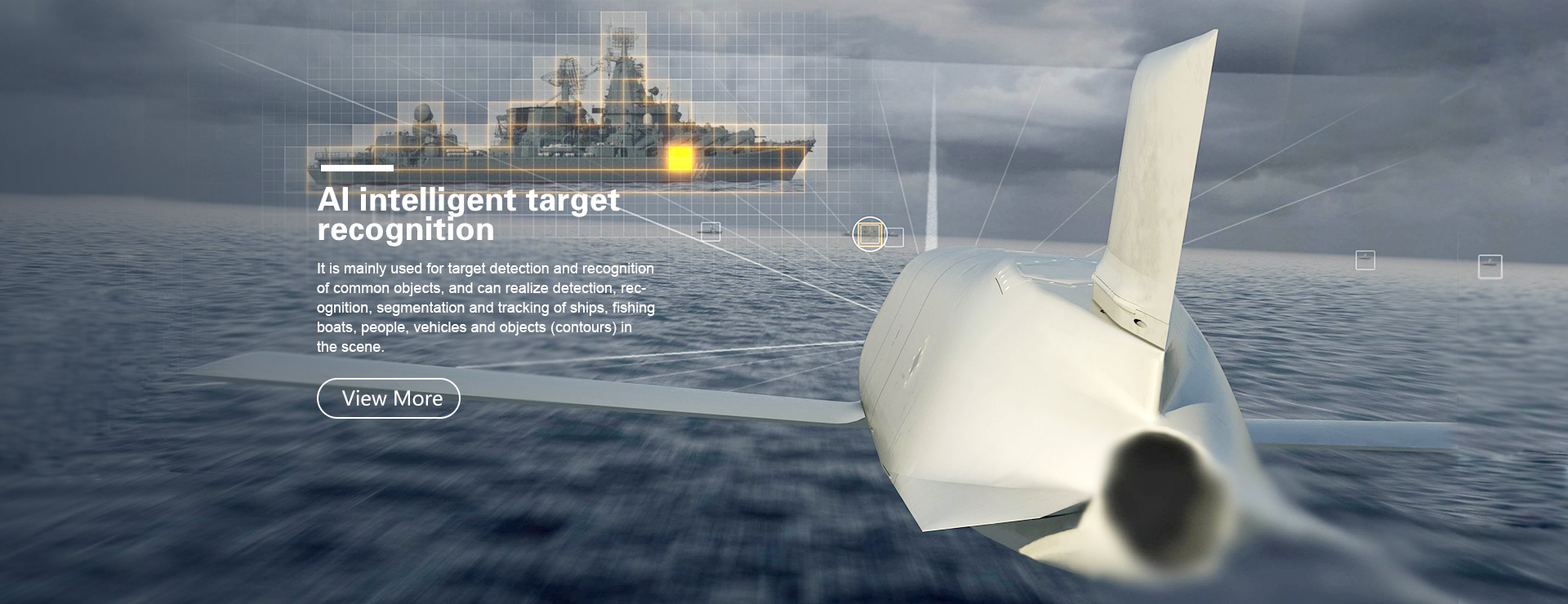

Infrared thermal imaging technology is applied to the regular monitoring and fault diagnosis of petrochemical equipment. It is mainly based on the principle of infrared radiation temperature measurement. It relies on the infrared imager to quickly and conveniently obtain the heat map of the measured object, according to the temperature difference of each part of the measured object, and the object. The temperature difference of the same part in different periods, combined with the equipment, device structure and other conditions to diagnose the operation of the equipment, so as to provide a basis for equipment status monitoring reports, as well as effective failure and maintenance reports. Compared with the traditional periodic shutdown test, this technology has very high precaution, initiative and flexibility in production efficiency and accident prevention.

In addition, oil spills are a major problem in oil pipeline transportation, and often cause huge economic losses and serious environmental pollution. Therefore, strengthening the inspection of oil pipelines has become an urgent problem for the petroleum industry. The infrared technology is applied to the inspection of oil pipeline inspection lines, and has a night inspection function, which can realize the all-weather inspection of the oil pipeline. The infrared camera has the characteristics of compact structure, small size, etc. It has the functions of infrared focusing system and high dynamic display, and the image is clear. Therefore, the infrared camera is an ideal tool for oil leak detection.

發(fā)送反饋

歷史記錄